If your seams are suddenly puckering, skipping, or looking just plain off, don’t panic and start blaming your fabric or machine. The real villain might be right under your nose (or needle plate): a dull or damaged sewing machine needle. Here's the thing about needles that no one wants to actually admit: your needle might look totally fine and it can still have something wrong with it. Your eyes just aren't good enough to see the problem!

Yes, that tiny piece of metal can cause big problems when it’s past its prime. Let’s walk through the most common seam troubles that point to a dull needle, and what to do about it.

🧵 Common Seam Issues Caused by a Dull Needle

1. Skipped Stitches

You’re sewing along, everything seems fine… until you realize the machine didn’t actually stitch that entire section.

Likely cause: A dull needle can't penetrate the fabric cleanly or may be slightly bent, causing the thread to miss the bobbin loop.

2. Puckering and Tunneling

You’re using stable fabric, your tension is fine, and yet your seams look like they’re trying to form mountains.

Likely cause: A blunt needle can distort the fabric as it punches through, especially on lightweight fabrics like rayon or voile.

3. Thread Breakage or Shredding

If your thread keeps snapping or looking frayed in the seam, your first instinct might be to blame the spool—but check your needle first.

Likely cause: A rough needle eye or nicked tip can cause friction that weakens or breaks your thread.

4. Thudding or Clicking Noises

Your machine should hum, not clunk.

Likely cause: Dull or bent needles often make weird noises as they struggle to pierce fabric. Don’t ignore the sound—it’s your machine crying for help.

5. Unexplained Tension Woes

If your upper or bobbin tension has gone haywire despite your best settings, you might be compensating for a tired needle without realizing it.

🔁 How Often Should You Change Your Needle?

Here’s the golden rule: Every 6–8 hours of sewing time—even if it doesn’t look damaged. And if you’re working with thick layers, metallic threads, or dense fabrics, change it even more frequently.

At Sew Club Supplies, we always say:

💡 “When in doubt, swap it out.”

🛠 Quick Needle Troubleshooting Checklist

-

✅ New needle installed?

-

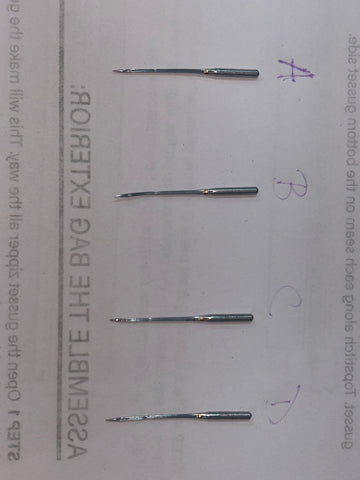

✅ Correct needle type for fabric? (Universal, ballpoint, stretch, etc.)

-

✅ Right needle size? (80/12 is great for most midweight projects)

-

✅ Fully inserted and facing the right way? (Flat side to the back on most machines)

Still having issues? Rule out other culprits like poor quality thread, incorrect bobbin winding, or a dusty bobbin case, but always start with the needle.

✂️ Make Needle Changes Easy

Running out of fresh needles is the worst; especially mid-project. That’s why our subscribers at Sew Club Supplies get high-quality sewing machine needles delivered when they need it. You’ll always have a new one on hand before your seams start suffering.

Add our needle recycling option to your plan and send us your used needles using the pre-paid envelope in your delivery. Clean studio, clean conscience.

Don’t let a dull needle ruin your stitch game.

Fresh needles = crisp seams, happy machine, and fewer headaches.

Happy sewing!

-E